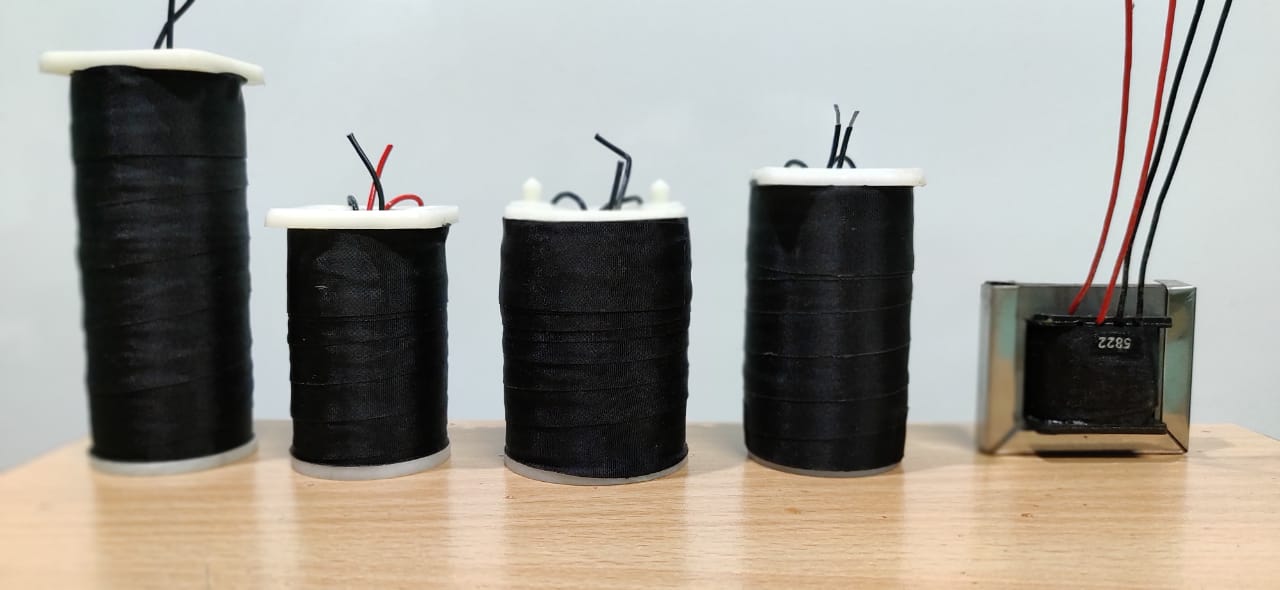

Coils

Railway Signalling QType Relay Special Purpose Coils and Transformers

| QN1 | QECX53 |

| QNA1 | QT2 4 & 9 ohms |

| QTA2 | QSPA1 |

| QECX61 | QS3 |

| QECX51 | QAA1K |

| QECX52 | QN1K |

| QSRA1 | QL1 |

| QNHX1 | QT1 |

| QNNA1 | TRANSFORMER |

| QNM1 | T51 |

| QBAT | T52 |

| QECX1 | T61 and T1 |

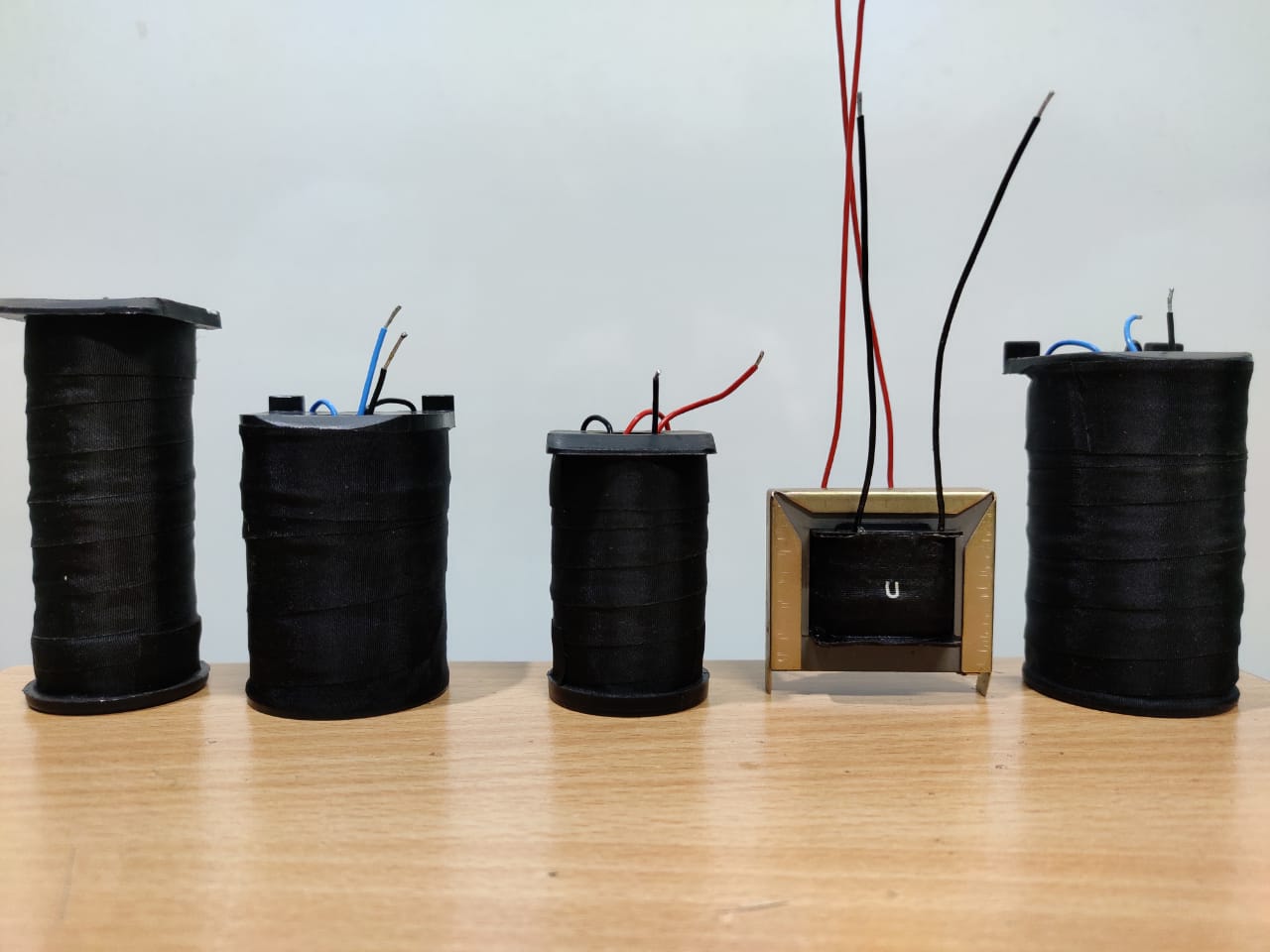

Inductor Coil

We are providing our clients Inductor Coil in a varied range of sizes and capacities. These coils are used to store the magnetic field around its circular path. In several electrical applications where movement or the rotation is involved, our offered coil suits the best. Owing to the top-rated copper core wire to fill the coil, we are able to supply highly qualitative and resilient product. Moreover, this undergoes through a series of stringent quality tests based on several set industrial parameters to ensure the top-notch performance of Inductor Coil.

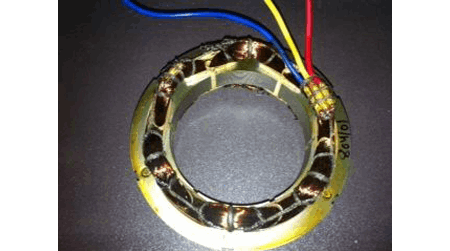

BDLC Fan Motor Coil

The main difference between BLDC and ordinary DC fans is the commutation method. A commutation is basically the technique of changing the direction of current in the motor for the rotational movement. In a BLDC motor, as there are no brushes so the commutation is done by the driving algorithm in the Electronics. The main advantage is that over a period of time, due to mechanical contact in a brushed motor the commutators can undergo wear and tear, this thing is eliminated in BLDC Motor making the motor more rugged for long-term use.